Thèmatique

DEA : Décharges Électriques et Aérosols

Responsable: Jean-Pascal BORRA

French version under progress from this English version of 02/2024

Membres de l'équipe

Chercheurs

| BORRA Jean-Pascal |

Directeur de Recherche |

| MARODE Emmanuel | Directeur de Recherche bénévole |

Ph-D students

| Philipp REMBE |

PhD Student, Bipolar Electrospray coagulation for catalytic hetero-aggregates, 2024-28 co-encadré avec Pr Weber (Directeur de thèse à 50%) Technical University of Clausthal |

Objectives, strategy and applications

At LPGP, the topic "Plasma-based aerosol processes" focuses on non-thermal plasmas controlled in atmospheric pressure electrical discharges. To highlight recent developments of atmospheric pressure Plasmas, confined plasma filaments with large ranges of operating conditions in terms of energy, fluxes and related gradients of temperatures and densities, are used as sources of:

- Charged species, like ions/electrons for aerosol charging.

- Reactive species, like radicals for polymerization or electron for salt reduction into Metal NP.

- Condensable vapors for Nucleation (Nanoparticle -NP- formation) and Nano Composite coatings.

Basic mechanisms implied for production, processing and measurement of solid/liquid particles suspended in gases (aerosol) are first identified by demonstrative experiments. Then, coupling plasma and aerosol sciences leads to applications for "Environment"(aerosol measurement and filtration) and "Materials" (multi-Metal NP and nanocomposite coatings), based on:

- Electro-thermal characterization and simulation of electrical discharges (Corona, streamer, spark and DBD) versus geometrical, thermal and fluid flow parameters to control:

- Charge and energy distribution of plasma filaments

- Dynamics of energy injection and deposition in the gas and on surfaces

- Electro-thermal couplings (Power, Flow rate, surface and gas Temperatures)

- Gas and Nanoparticle characterisation versus plasma operating conditions to identify :

- Mechanisms of production of condensable species (for physical or reactive nucleation)

- Mechanisms of heat and mass transfers (diffusion, convection, adiabatic expansion)

- Conditions of nucleation, coagulation and charging Gas and Nanoparticle characterisation versus plasma operating conditions to identify:

- Kinematics of solid/liquid nanoparticles suspended in the gas -> Definition of optimal plasma conditions versus targeted application

- Development of experimental test and sampling facilities of proposed processes, applied to:

- Environment (Aerosol charging for filtration and size distribution measurement)

- Materials (Tailored Nanoparticles-NP-, composite nano-structured powders and coatings)

Research topics

- Discharge physics of non-thermal atmospheric pressure plasma: electro-thermal characterization of Corona, Streamer, Spark and Dielectric Barrier Discharges. Readers can refer to [ 3, 10, 11, 17, 18, 22, 25, 31, 33, 38, 40, T14, T15, T19, T21, T27, T30, T33 ]

-

Nucleation: non-thermal plasma filaments in inert gases, streamers and sparks, are used for the synthesis of NP by plasma-surface vaporization of any material (Metal, MOx, Polymer [18, 20, 24, 26, 44, T30, T31]). Operating plasma parameters, like energy per filament and dynamic of energy deposition on surfaces, can be tuned to control surface heating, melting, vaporization as well as adiabatic expansion and cooling of the vapor plume, leading to NP by physical nucleation. In other words, plasma properties can be adjusted to control the conditions of NP synthesis and related properties (cf. Ex.1, [14, 19, 24, 26, 44, T30, T31, T34]).

Otherwise, reactive nucleation can be used for post-DBD in-flight coating of catalytic Pt NP, by PE-CVD of TEOS (cf. Ex.2, [12, T34]).

-

Plasma processing of Aerosol

Aerosol charging and kinematics in plasma chargers for diagnostic: Discharge and ion currents are used to achieve stable size-charge relations, required for data inversion of electrical mobility into size distribution (PM10 to 0.1), with unipolar Corona ions (Ramen® and CSIC 2007-10 [23, 29], IRSN 2009-16 [6, 7, 11, T32] and NCTU Taiwan 2020-24 [1, 4, T35]) or bipolar ions from DBD (Palas® 2013-16, [3, 10, 25, 26, T33]).

Aerosol injection in DBD for plasma activated reactions (polymerization, ox-red): liquid/solid particles can be injected directly in DBD for simultaneous polymerization and reduction of salt into Metal NP, detailed for plasmonic nanocomposite films (cf. Ex.3, [2]).

Otherwise, post-DBD have also been used for softer reactive conditions to preserve the initial monomer functionalities in the final grafted polymer coating. This polymerization of liquid precursor for coating with functional polymers is detailed in [16, 21, 27, 28, 31, 32, 44, T28, T29])

- Electro-spray (EHD fragmentation of liquid jets and charged aerosol kinematics): this droplet generator can be used for bipolar mixing of droplets, leading to suspended microreactors with selected stoichiometry of reactants so-mixed, for the synthesis of tailored nano-structured composite particles, eg with tunable stoichiometry of muti-Metal oxides particles [41, 45, T23] as well as for coatings.

Cooperations (2019-2023)

- Since 2008 : TU Clausthal, Germany / Metal NP production and in-flight SiOx coating

TU Clausthal www.mvt.tu-clausthal.de/

TU Clausthal www.mvt.tu-clausthal.de/ - 2020-21: CNRS Task Force about C19 / Filtration efficiency versus cleaning and decontamination methods tested for reuse of FFP2

- 2020-2024: NCTU Taiwan / particle size and concentration measurement by Corona charger, non-bouncing impactors and faraday cage electrometers (20-560 nm)

- 2021-22 : Institut National de Recherche sur les Risques et la Sécurite professionels (INRS) / Indoor Air Quality versus aerosol formation due to ionisers used as air purifiers

INRS www.inrs.fr

INRS www.inrs.fr - 2021-25: PROMES, LAPLACE and LSPM for PLASSEL ANR / Aerosol droplet evaporation dynamic for nanocomposite coating by DBD with Gold NP embedded in a C polymer matrix

- 2023 : DMCO SME / Evaluation of acoustic waves efficiency on filtration performances.

-

IPPGG Laboratoire Procédés Plasma - Matériau (2PM) de l'Institut de Recherche de Chimie Paris, Institut Pierre-Gilles de Gennes pour la micro-fluidique

équipe 2PM

équipe 2PM

Ex.1 TAYLORED NANOPARTICLE SYNTHESIS (Compo, size, structure) versus plasma conditions of formation with different plasma filaments (micro-discharge in DBD, streamer, spark in corona)

Plasma-based aerosol processes for catalytic properties of multi-Metal nanoparticles (NP)

Nucleation in plasmas is a long term topic of LPGP depicted in [14, 18, 19, 20, 24, 26, 31, 40, 44, T14, T15, T27, T30, T31, T33, T34].

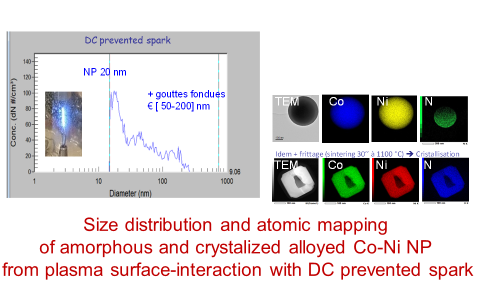

Atmospheric pressure Plasma in nitrogen and air are confined in time and space, as plasma filaments lasting a few ns, from tens to few micrometers in diameter. The production of condensable species and nucleation necessarily occurs either from cooling of expanding vapor plumes produced by plasma-surface interaction, depicted just below, or from injection of gaseous precursors in the plasma for reactive nucleation (cf. Ex.2,).

Tuning plasma properties, like energy per filament and dynamic of energy deposition on surfaces, is a simple way to control the conditions of NP synthesis and related properties.

Indeed, NP are formed by condensation (or nucleation) of hot vapors in expanding vapors jets/clouds from the electrodes (Mo, W, Al, Fe, Ni, Cu, Sn, Zn, Au, Ag, Pt) and from dielectric material (alumina).

We confirmed this mechanism with different alloyed electrodes with IJL-Nancy. However, core-shell NP of Cu@ZnO are produced from Cu-Zn alloys, while alloyed Co-Ni NP are synthesized in similar plasma conditions from Co-Ni alloys.

Going one step further, the effect of cooling rates of expanding vapor jets on the structure of nanoparticules, is under investigation to select plasma operating conditions (controlling the filaments electro-thermal properties) versus targeted composition and structure of NP. Metastable multi-Metal crystal structures are expected with respect to cooling rates in prevented spark, typical of those required for high entropy alloys formation (over 105 K.s-1). The goal is to control optical properties, like UV photoemission and catalytic properties of multi-Metal nanoparticles.

Ex.2 Plasma-based COATINGS PROCESSES for NANOCOMPOSITE MATERIALS:

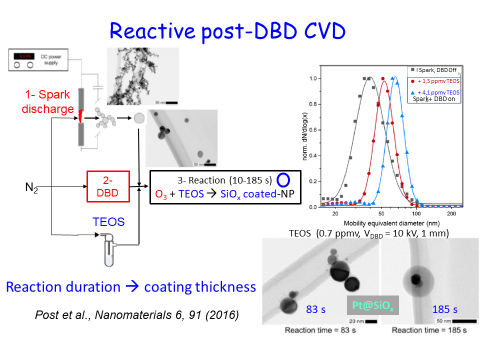

In-flight coating of NP by post-DBD reactive PE-CVD of gas precursor for thermo-stable SiO2 coating of photocatalytic NP (2015-19, 1 PhD in collaboration with Prof.Weber from TU Clausthal, [12, T34])

Coatings of agglomerated NP is used to improve thermostability to limit the surface reduction by melting of catalytic agglomerates. Silicon oxide is one of the preferred nontoxic and almost inert coating materials. Liquid coating methods imply washing, drying and separation steps, with residual impurities from solvents contaminating the final solid coatings. Therefore, gas-phase coating methods are generally preferred (e.g. atomic layer deposition and plasma enhanced chemical vapor deposition PE-CVD). Here, a plasma-based aerosol process has been proposed and validated for in-flight coating of particles by post-Plasma SiOx coating.

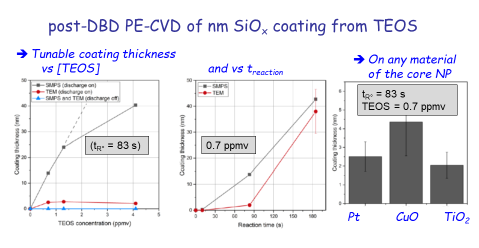

It has been shown that non-thermal plasma filaments induced in a dielectric barrier discharge (DBD) at atmospheric pressure trigger post-DBD gas phase reactions with tetraethyl orthosilicate (TEOS) precursor downstream of the DBD.

|

|

|

Fig: (left) Set-up for post-DBD in-flight SiOx coating of NP : 1) Pt- catalytic NP production by spark-surface interaction, followed by 2-3) post-DBD Reactive Nucleation also called PE-CVD ; (right) size distributions of Pt- NP from sparks only, compared with the same coated aerosol with DBD on for 2 TEOS concentrations |

Such post-DBD injection of gaseous organo-silicon precursor avoids electrode coating and discharge evolution to achieve a steady fluxes of active species downstream the so-stabilized DBD, with subsequent controlled thickness of SiOx coatings, versus TEOS concentration and reaction duration.

Homogeneous solid SiOx coatings of spherical and agglomerated metal and metal oxide nanoparticles (Pt, CuO, TiO2) have been achieved with controlled thickness from nanometer to micrometer.

The reader can find details on (i) operating conditions to be tuned to cover preferentially the interparticle contact zones between primary particles of agglomerates, (ii) improved thermal stability, related to higher sintering temperatures of so-coated agglomerates of catalytic Pt-NP, as well as (iii) tunable photoactivity catalytic Pt-NP agglomerates.

Ex.3 Plasma-based COATINGS PROCESSES for NANOCOMPOSITE MATERIALS:

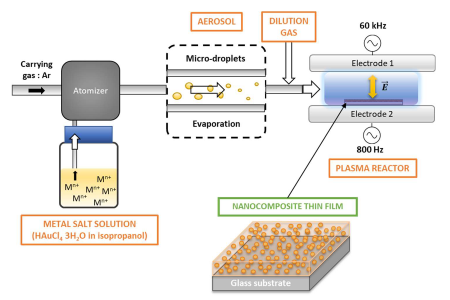

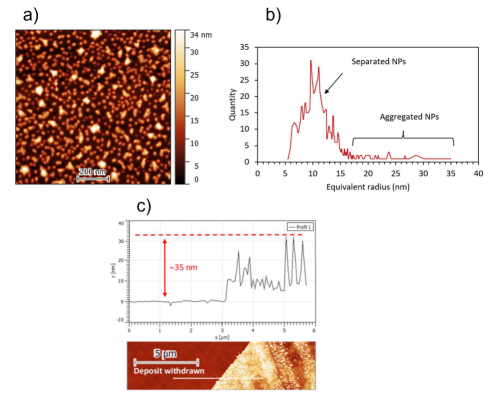

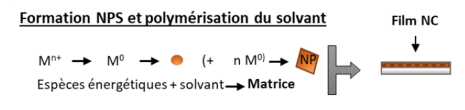

Synthesis of gold NP@polymer nanocomposite (NC) coating, by metal salt NP reduction with simultaneous polymerization of evaporated monomer in DBD (2021-25, ANR PLASSEL, [2])

Different options have been tested for deposition of NC polymer films on large areas with DBD. Most use a liquid aerosol, i.e. droplets of liquid monomers suspended in a carrier gas to the plasma.

For NC coatings, the injection of a liquid suspension of premade NP in a polymerizable solvent leads to NC films with NP eventually aggregated. Otherwise, synthesis of NP by plasma reduction of a metal precursor is investigated with a dissolved/crystalized Gold salt injected in DBDs.

This ANR project highlights the interest of atmospheric pressure DBD for one-step and safe-by-design Aerosol-Assisted plasma synthesis of Nano-Composite (NC) polymer films, containing 5 to 50 nm Au NP. Indeed, Metal@polymer NC films have been processed with Gold NP, for plasmonic properties.

A solution of Gold salt in isopropanol- (HAuCl4, 3H2O) is first nebulized into 0,3 µm droplets suspended in Ar. Aerosol size distribution measurements support fast evaporation before injection into the DBD of solid salt nanoparticles (NP) of about 30 nm diameter with eventual traces of solvent.

|

|

|

|

|

Fig: (left) Set-up for NC coating by AP-PECVD, where metal salt solution is nebulized as a liquid aerosol, ie as droplets suspended in Ar flow injected in DBD, and (Right) AFM of a NC film from Ar DBD; a) topography of the coating b) grain size distributions inferred from AFM image analysis and c) scratch test profile measured on the white line of the scratched sample image. (Bottom) mechanism of NP and polymer formation by reduction of Au3+ salt NP and simultaneous has phase polymérisation of evaporated isopropanol |

|

Size distributions at several positions between the atomizer and the plasma support that:

- droplets produced by liquid fragmentation in the atomizer by pneumatic fragmentation of a solution of gold salt in isopropanol evolve in size and concentration, due to evaporation, losses to the walls and coagulation by diffusion of NP, as well as by dilution.

- this liquid aerosol reach the DBD, as 30-40 nm salt particles, expected from fast evaporation of initial 300 nm droplets with 1.6 mg/mL Au3+ salt dissolved in isopropanol. Hence, the aerosol injected into the DBD is made of solid crystallized salt NP suspended in Ar with traces of Isopropanol.

Morphological and chemical analyses show that the gold salt is reduced by DBD leading to Gold Metal NP, with 8nm modal diameter derived from XRD, confirming the size distribution of injected salt aerosol. The reduction of 30-40 nm Au3+ NP into 8nm, Au0 deposited NP, thus occurs in plasma on injected crystalized gold salt NP resulting from IPA evaporation.

The reduction mechanism of such suspended salt NP is under investigation (free electrons, radicals from VOC decomposition,…) to account for smaller Au° NP reported with NH3 addition in Argon.

Ammonia may also act as electron scavengers, thus competing with salt reduction and could also affect the charge and kinematics of NPs upto the substrate. Indeed, Ammonia affects plasmonic properties of these NC film, related to size, concentration and composition of embedded Au° NPs.

Publications DEA@LPGP since 1997

cf. HAL: authIdHal 289945 - ORCID 0000-0002-2020-0478 - Scopus ID 6603938085 ( links verified on 01.01.2024 )

2024

-

1. Gong W-C, Jidenko N., Le T.-C., Lin C-H, Li Y.-R., Borra J-P, and Tsai C.-J. (2024) Novel electrostatic particle sizer (NEPS) for long-term submicron and ultrafine particle size distribution monitoring, Process Safety and Environmental Protection, submitted in dec. 2023.

2023

-

2. Perdrau, A., Barros, N., Rincón, R., … Borra J-P, Fanelli, F., Massines, F. (2023) Synthesis of Gold NPContaining Thin Films from Metal Salt Injection in Ar or Ar–NH3 DBDs, Plasma Chemistry and Plasma Processing, 2023, 43-6, pp. 1749–1772. (HAL: hal-04396303 ; DOI: 10.1007/s11090-023-10400-4 ; Scopus )

-

3. Jidenko, N., Mathon, R., Gérard, V., Adédiran, A.M., Borra, J.-P. (2023) Dielectric barrier discharge as bipolar ion source for aerosol charging: Application to filtration, thin film, and aerosol size measurement Journal of Electrostatics, 2023, 126, 103856. ( HAL: hal-04309937v1; DOI (doi:%2010.1016/j.elstat.2023.103856) ; Scopus: eid=2-s2.0-85171466426)

-

4. Gong, W.-C., Jidenko, N., Li, Y.-R., Le T.-C.,Borra, J.-P., Tsai, C.-J. (2023), PM0.1 non-bouncing impactor (NBI) for ultrafine particle mass and number measurements Journal of Aerosol Science, 2023, 174, 106249. ( HAL: hal-04309790v1 hal-043097902022 , DOI: 10.1016/j.jaerosci.2023.106249 , Scopus: eid=2-s2.0-85167795991)

2022

-

5. Cario A.; Aubert G.; Alcaraz J-P; Borra J-P; Jidenko N.; Barrault M. ; Bourrous S.; Mocho V.; Ouf F.; Marre S., Cinquin, P., Aymonier, C. (2022) Supercritical carbon dioxide-based cleaning and sterilization treatments for the reuse of filtering facepiece respirators FFP2 in the context of COVID-19 pandemic, Journal of Supercritical Fluids, 2022, 180, 105428; (HAL: hal-03384956 ; Scopus: eid=2-s2.0-85116822277 )

2021

-

6. Jidenko, N., Bouarouri, A., Borra, J.-P. (2021) Effect of aerosol concentration on post-corona unipolar diffusion charging: Ion density retro-controlled by aerosol space charge versus geometry of ion-aerosol mixing, Aerosol Science and Technology, 2021, 56(2), pp. 146–159. (hal-03364345> ; DOI: 10.1080/02786826.2021.1984384 ; Scopus)

-

7. Jidenko, N., Bouarouri, A., Gensdarmes, F., Maro. D, .Boulaud, D., Borra, J.-P. (2021) Post-corona unipolar chargers with tuneable aerosol size-charge relations: Parameters affecting ion dispersion and particle trajectories for charger designs, Aerosol Science and Technology, 2021, 55(1), pp. 12–23. ( DOI: 10.1080/02786826.2020.1817310 ; hal-02940503 ; ARXIV: 2011.00065)

2018

-

8. Borra JP, (2018) Editorial introduction of the special issue on Electrosprays for the JAS, Journal of Aerosol Science Volume 125, November 2018, p1. DOI 10.1016/j.jaerosci.2018.08.008, HAL: hal-02415713

-

9. Borra J.-P. (2018), Review on Water Electro-Sprays and applications of charged droplets with focuss on the corona-assisted cone jet mode for High Efficiency Particles Air Filtration by wet electro-scrubbing of aerosol, Special Issue of J. Aerosol Scence. on Electro-Sprays, guest editor Borra JP Volume 125, November 2018, pp 237-250 DOI: doi.org/10.1016/j.jaerosci.2018.04.005 - ; HAL: hal-02415646

2017

-

10. Mathon, R., Jidenko, N., and Borra, J.-P. (2017). Ozone-free post-DBD aerosol bipolar diffusion charger: Evaluation as neutralizer for SMPS size distribution measurements. Aerosol Science and Technology, 51(3), 282-291. doi: 10.1080/02786826.2016.1265082 (free eprint) - HAL: hal-03244467

2016

-

11. Bouarouri A., Jidenko N., Gensdarmes F., Maro D., Boulaud D., Borra J.-P. (2016) Ion current density profiles in negative corona gaps versus EHD confinements, Journal of Electrostatics, 82, pp 88-95; DOI: 10.1016/j.elstat.2015.08.005 - HAL: hal-02558448

-

12. Post P, Jidenko N, Weber A.F., and Borra J.-P. (2016) Post-Plasma SiOx Coatings of Metal and MetalOxide Nanoparticles for Enhanced Thermal Stability and Tunable Photoactivity Applications Nanomaterials 6-5, 91; DOI: 10.3390/nano6050091 - HAL: hal-03246951

-

13. Alonso M., Borra J.P (2016). A method to limit uncertainties in aerosol properties determined from comparative measurements Journal of Aerosol Science, Volume 91, January 2016, Pages 15-21, DOI: 10.1016/j.jaerosci.2015.09.005

2015

-

14. Borra J.-P., Jidenko N., Hou J., Weber A. (2015) Vaporization of bulk metals into single-digit nanoparticles by non-thermal plasma filaments in atmospheric pressure dielectric barrier discharges, Journal of Aerosol Science, 79, 109–125; DOI: 10.1016/j.jaerosci.2014.09.002

2014

-

15. Alonso M, Gómez V., Borra J.-P. (2014) Determination of the Mean Mobility of Aerosol Nanoparticles Classified by Differential Mobility Analyzers, Aerosol Science and Technology, 48:12, 1217-1225, DOI: 10.1080/02786826.2014.973931

2012

-

16. Feature article Borra J-P, Valt A., Arefi-Khonsari F., Tatoulian M. (2012) Atmospheric pressure deposition of thin functional coatings: polymer surface patterning by DBD and post-discharge polymerization of liquid vinyl monomer from surface radicals, Plasma Processes and Polymers, Special Issue "Cold Atmospheric Plasmas for Thin Films and Nanomaterials" DOI: 10.1002/ppap.201100210

-

17. Jidenko N and Borra JP, (2012) Self-cleaning maintenance-free aerosol filter by nt-plasma DBDischarges at atmospheric pressure, J. Hazard. Mater, 235, pp 237-245; DOI: 10.1016/j.jhazmat.2012.07.055

2011

-

18. Topical Issue Borra J-P, Jidenko N, Dutouquet C, Aguerre O., Hou J., Weber A.(2011) Nano-droplet ejection and nucleation of materials submitted to non-thermal plasma filaments Eur. Phys. J. Appl. Phys., 56, 1286-0042, 24019 (7 p) from "18th Int. Colloq. Plasma Processes, DOI: 10.1051/epjap/2011110201 - HAL: hal-00746219

-

19. Hou J., Jidenko N., Borra J-P. and Weber A. P.,(2011) Production of metal Nanoparticles in non-thermal filamentary-DBD Chemie Ingenieur Technik,CIT, 0009-286X, Vol. 83-12, pp 2161–2169, DOI: 10.1002/cite.201100057

2010

-

20. Bau S, Witchger O, Gensdarmes F., Thomas D, Borra J-P (2010) Electrical properties of airborne nanoparticles produced by a commercial spark-discharge generator, J. of Nanoparticle Research ; DOI: 10.1007/s11051-010-9856-y - HAL: hal-00517679

-

21. Borra J-P, Valt A, Arefi-Khonsari F, et al (2009) Polymer surface processing by AP DBD for post-discharge grafting of washing-resistant coating Book Series: Materials Science Forum Volume: 638-642 Pages: 524-529 Part 1-4, DOI: 10.4028/www.scientific.net/MSF.638-642.524

-

22. Jidenko N and Borra JP Temperature profiles in filamentary dielectric barrier discharges at atmospheric pressure JPhys D: Applied Physics,Volume: 43 Issue: 29 Article Number: 295203 DOI: 10.1088/0022-3727/43/29/295203 - HAL: hal-00569657

2009

-

23. Alonso M, Alguacil F.J, Borra JP, (2009) A numerical study of the influence of ion-aerosol mixing on unipolar charging in a laminar flow tube, Journal of Aerosol Science, ISSN: 0021-8502,, 40, 693-706, DOI: 10.1016/j.jaerosci.2009.04.004

-

24. Borra JP, Bourgeois E. et Jidenko N. (2009) Atmospheric pressure plasmas for aerosols processes in materials and environment, European Physical Journal of Applied Physics., ISSN: 0022-3727, Vol. 47-issue 2, 7pp, art. N° 22804, DOI: 10.1051/epjap/2009088 - HAL: hal-00486864

-

25. Bourgeois E, Jidenko N, Borra JP (2009) DBD as a post-discharge bipolar ions source and selective ion-induced nucleation versus ions polarity, J.Phys D, Vol. 42, issue 20, (Article Number: 205202), 9pp, DOI: 10.1088/0022-3727/42/20/205202

2008

-

26. Borra JP (2008) Charging of aerosol and nucleation in atmospheric pressure electrical discharges Plasma Phys. Control. Fusion 50 124036-124045; DOI: 10.1088/0741-3335/50/12/124036

2007

-

27. M. Tatoulian, Gallino E, Jafari R, Arefi F, Tatoulian L, Borra J-P, Lewis F, Mantovani D, (2007) Plasma and Electrospray deposition for biocompatibility of stents, Materials Science Forum. 539-543,.529-534 ; DOI: 10.4028/0-87849-428-6.529

-

28. Tatoulian M., Arefi-Khonsari F., Borra J-P. , (2007) Deposition of Organic Coatings at Atmospheric Pressure from Liquid Precursors, Plasma Process. And Polym., 4, 360–369 ; DOI: 10.1002/ppap.200600187

-

29. M. Alonso, F.J. Alguacil, N. Jidenko and J.P. Borra, (2007) Deposition of ultrafine aerosol particles on wire screens by simultaneous diffusion and image force, JAS 38 1230-1239 ; DOI: 10.1016/j.jaerosci.2007.09.004

-

30. N. Jidenko, C. Jimenez, F. Massines and J.P. Borra, (2007) Nano-particle size-dependent charging and electro-deposition in dielectric barrier discharges at atmospheric pressure for thin SiOx film deposition J. Phys. D: Appl. Phys. 40 4155–4163 ; DOI: 10.1088/0022-3727/40/14/009

2006

-

31. Borra JP review Aerosol production and processing by atmospheric Pressure Electrical Discharges: powder production, coatings and filtration, J. Phys. D : Appl. Phys 39, 19-54; DOI: 10.1088/0022-3727/39/2/R01

-

32. Tatoulian M., Arefi-Khonsari F., Tatoulian L., Amouroux J. and Borra JP , (2006) Deposition of Polyacrylic Acid Films by post-discharge EHD atomisation , Chem. Materials, 18, 5860-5863 ; DOI: 10.1021/cm060066e

-

33. Jidenko N. and Borra J.P. Electrical characterization of microdischarges produced in dielectric barrier discharge in dry air at atmospheric pressure, J. Phys. D: Appl. Phys. 39, pp. 281–293; DOI: 10.1088/0022-3727/39/2/008

2005

-

34. Bastide S, Duphil N, Levy-Clément C, Borra JP (2005) WS2 closed nanoboxes synthesized by spray pyrolysis, Advanced Mat., 18-1, 106-109; DOI: 10.1002/adma.200501735

-

35. Jidenko N., Borra JP (2005) Kinematics of charged nanometric particles in silent discharge, J. PhysD: Appl. Phys 38 617-620 ; DOI: 10.1088/0022-3727/38/4/014

2004

-

36. Borra JP, Ehouarn P., Boulaud D. (2004) EHD Pulverization of Water Stabilized by Electrical Discharges : Principle, Functioning Domains and Droplet Properties, J. of Aerosol Science 35-11 1313-1332; DOI: 10.1016/j.jaerosci.2004.05.011 - HAL: hal-03479574

-

37. Unger L., Boulaud D., Borra JP (2004) Unipolar field charging law in a DC corona discharge: effect of particle shape J. of Aerosol Science 35-1 965-979; DOI: 10.1016/j.jaerosci.2004.01.006

2002

-

38. Petit M., Jidenko N., Borra JP (2002) Electrical characterization of gas discharges in relation with their properties using a numerical treatment : application to DBD Rev. Scientific Instrument 73-7 2705-2713 ; DOI: 10.1063/1.1484236

2001

-

39. Ehouarn P., Unger L, Borra JP Properties of water droplets produced by Electro-HydroDynamic pulverisation for the collection of particulate plasma by-products J. High T Mat. Processes 5-3 333-344 ; DOI: 10.1615/hightempmatproc.v5.i3.40

2000

-

40. Odic E, Parisi L, Goldman M, Borra JP, (2000) Temperature effect on Plasma Chemistry.., contribution à Electrical Discharges for Environmental Purposes, ed. Veldhuizen, Raizers Book, USA, pp279-31

1999

-

41. Borra J-P, Camelot D, chou KL, Marijnessen JCM, scarlett B Bipolar coagulation and mixing for powder production, J. of Aerosol Science 30-7 945-958 ; DOI: 10.1016/S0021-8502(98)00757-5

-

42. Borra J-P, Tombette Y., Ehouarn P. Influence of the electric field (symmetry, evolution, intensity and divergent) on the mode of Electrohydro-dynamic Pulverization of liquids related to discharge regimes, J. of Aerosol Science 30-7 913-925 DOI: 10.1016/S0021-8502(98)00779-4

-

43. Hartman RPA, Borra J-P, Brunner D, Marijnessen JCM, Scarlett B Evolution of EHD sprays produced in cone-jet mode, A physical Model J. Electrostat. 47 143-170; DOI: 10.1016/S0304-3886(99)00034-0

1998

-

44. Borra J-P, Boulaud D., Goldman M., Goldman A. Aerosol production by DC high pressure cold plasmas, J. of Aerosol Science 29-5/6 661-674 ; DOI: 10.1016/S0021-8502(97)00453-9

1997

-

45. Borra J.P., Camelot D., Marijnessen J., Scarlett B. A new production process of powders with defined properties by EHDA of liquids and post-production electrical mixing, J. Electrostat. 40-41 633-638 ; DOI: 10.1016/S0304-3886(97)00065-X

-

46. Borra JP, Roos RA, Renard D, Lazar H, Goldman A, Goldman M. Electrical and chemical consequences of point discharges in a forest during a mist and a thunderstorm J. PhysD: Appl. Phys. 30 84-93 ; DOI: 10.1088/0022-3727/30/1/011

Thesis DEA@LPGP since 1997 (35)

- 1 supervided by Gildas HARTMAN

-

T1. BENALI Mohamed Nadjim (1999) Etude experimentale et theorique de la conductivite de l'air a pression atmospherique dans un systeme d'electrodes cylindriques concentriques, en dessous du seuil de l'effet couronne.

www.theses.fr/1999PA066658

www.theses.fr/1999PA066658

-

-

1 supervided by Robert HAUG

-

T2. DESORBAIX G. (1998)

-

- 2 supervided by Gérard BERGER

-

T3. HADAJI Ramzi (1999). Modelisation de la capture de la foudre par paratonnerre.

www.theses.fr/1999PA066569

www.theses.fr/1999PA066569 -

T4. AÏT-AMAR Sonia (2006). Modélisation de la protection contre la foudre par paratonnerre.

www.theses.fr/2006PA112323

www.theses.fr/2006PA112323

-

- 6 supervided by Emmanuel MARODE

- T5. SAMSON Sophie (1997) Etude de la reactivite physico-chimique d'une decharge filamentaire a pression atmospherique, dans l'air. Application au controle de la pollution

www.theses.fr/1997PA112232

www.theses.fr/1997PA112232 -

T6. MACHALA Zdenko (2000) Continuous and transient electrical discharges, streamer triggered, at atmospheric pressure, for the removal of volatile organic compounds (VOC); Les decharges electriques continues et transitoires, induites par streamer, sous pression atmospherique, pour la destruction des composes organiques volatils (COV)

www.osti.gov/etdeweb/biblio/20559215

www.osti.gov/etdeweb/biblio/20559215 -

T7. DESCHAMPS Nathalie (2000/10)

-

T8. DESSANTE Philippe (2000/10) Modélisation d'une décharge électrique de type streamer dans l'air à haute-pression sous géométrie non uniforme

hal.science/tel-01334291 ( online pdf )

hal.science/tel-01334291 ( online pdf ) -

T9. TARDIVEAU Pierre (2002/01) Contribution à l'étude du déclenchement de la combustion par décharge électrique en milieu diphasique

www.theses.fr/2002PA066472

www.theses.fr/2002PA066472 -

T10. DENIZET C. (2002)

- T5. SAMSON Sophie (1997) Etude de la reactivite physico-chimique d'une decharge filamentaire a pression atmospherique, dans l'air. Application au controle de la pollution

- 12 supervided by Max et Alice GOLDMAN:

-

T11. SMIRDEC Marc (1997) La decharge couronne continue en milieu humide. Caracterisation des especes produites dans une atmosphere controlee. Phenomene de pollution et pouvoir depolluant

www.theses.fr/1997PA066728

www.theses.fr/1997PA066728 -

T12. PANAGET Marie-Pierre (1997) Etude en laboratoire des effets physico-chimiques induits par les pertes electriques des lignes de transport a haute tension

www.theses.fr/1997PA066152

www.theses.fr/1997PA066152 -

T13. KREISSL Bernhard (1998) Influence des lignes de transport electrique a haute tension sur la chimie atmospherique en correlation avec les conditions meteorologiques

www.theses.fr/1998PA066189

www.theses.fr/1998PA066189 -

T14. ODIC Emmanuel (1998, coENSCP) Etude d'une decharge moyenne frequence avec barriere dielectrique, ainsi que de la reactivite chimique du plasma genere. Application au traitement d'effluents gazeux charges en composes organiques volatils

www.theses.fr/1998PA066262

www.theses.fr/1998PA066262 -

T15. PARISSI Ludovic (1999, coENSCP) Etude d'un procede de traitement d'air charge en composes organiques volatils par decharge moyenne frequence avec barriere dielectrique : mecanismes mis en Œuvre et recherche d'optimisation

www.theses.fr/1999PA066689

www.theses.fr/1999PA066689 -

T16. KOCH S => BOUSQUET S. (2000 ou 2001, co EEI ?)

-

T17. DELAVEAU Sophie (2001, coEEI) Stérilisation par plasma : mécanismes d'interphase impliqués dans l'inactivation des spores bactériennes traitées par les effluents chimiques d'une décharge couronne

www.theses.fr/2001PA066569

www.theses.fr/2001PA066569 -

T18. DAOU Fatma (2002, coENSCP) Etude expérimentale d'un procédé de dépollution par décharge couronne à barrière diélectrique type pointe(s) - plan : rôle de la simulation numérique et du marquage isotopique

www.theses.fr/2002PA066488

www.theses.fr/2002PA066488 -

T19. DUPRE S. (2002/12, coENSCP)

-

T20. DHAINAULT M. (2003/09, coEEI)

-

T21. PETIT M. (2003, coEEI)

-

T22. DODET Bénédicte (2005, coEEI) Etude des propriétés oxydantes de mélanges gazeux activés par décharge électrique à pression atmosphérique : interaction avec un matériel biologique, sous la direction de Emmanuel Odic,

www.theses.fr/2005PA112335

www.theses.fr/2005PA112335

-

- 15 PhD supervised by JP Borra:

-

T23. CAMELOT D. Bipolar Mixing process for powder production, T Univ. Delft, 1997 (80% co-TUDelft)

-

T24. HARTMANN R. EHD fragmentation of liquid and spray development, 1998 (50% co-TUDelft)

-

ODIC E. Traitement de COV par DBD, Univ. Paris VI, 1998 (25% co-M&A Goldman)

-

PARISSI L. Mécanismes et procédé déCOV par DBD, Univ Paris VI, nov 1999 (25% co-M&A Goldman)

-

T25. EHOUARN Pascale, Pulvérisation électro-hydrodynamique de liquide stabilisée par décharges électriques pour le traitement d'effluents particulaires , Univ. Paris XI, avril 2001

www.theses.fr/fr/2001PA112356

www.theses.fr/fr/2001PA112356 -

T26. UNGER Lomig Charge d’aérosol par décharge Couronne, Université Paris-sud, déc.2001,

www.theses.fr/2001PA112308

www.theses.fr/2001PA112308 -

T27. JIDENKO Nicolas, Caractérisation électrique et couplages électro-thermiques des décharges à barrières diélectriques dans l'air à pression atmosphérique : faisabilité de l'électrofiltration d'aérosol, Université Paris-sud, déc. 2004

www.theses.fr/fr/2004PA112328

www.theses.fr/fr/2004PA112328 -

T28. TATOULIAN Ludovic. PostDBD Electrospray coating par polym, Univ. Paris VI, déc 06 (80% co-ENSCP)

www.theses.fr/2006PA066415

www.theses.fr/2006PA066415 -

T29. WALT A. Dépôt par plasma basse pression et DBD, Univ. Paris VI, fév. 2008 (50% co-ENSCP)

-

T30. BOURGEOIS Emilie, Nucléation par plasma non-thermique, Univ. Paris-sud, nov. 2010

-

T31. HOU Jun, Production de nano-poudres par DBD, Univ. de Clausthal, Avril 2012 (50% co-TUC)

-

T32. BOUARROURI Assia, Mesure à 10 Hz de taille d’aérosol par plasmas, Université Paris-sud, nov. 2014

www.theses.fr/2014PA112399

www.theses.fr/2014PA112399 -

T33. MATHON R. Faisabilité d’un neutraliseur d’aérosols en post-DBD, Univ. Paris-Saclay, déc 2015.

www.theses.fr/2015SACLS261

www.theses.fr/2015SACLS261  theses.hal.science/tel-01343294

theses.hal.science/tel-01343294 -

T34. POST Patrick. In-Flight SiOx coating of NP by post-plasma CVD process, TUClausthal, 2019 (50%, co-TUC) (

POST Patrick PhD )

POST Patrick PhD ) -

T35. GONG W.C., Particle measurements by post-corona charger impaction, Taiwan Univ, Nov. 2023 (50%)

-

En souvenir de Max Goldman

Max Goldman s'est éteint dans les monts de Jérusalem, à l'aube du dimanche 13 août 2017, à l'âge de 86 ans.

Après des débuts de carrière à la Défense Nationale et au CEA, il avait intégré le CNRS en autodidacte, avec des diplômes du CNAM et un doctorat d'Université sur les décharges dans le vide pour l'élaboration d'un tube de radiographie éclair. Puis engagé comme sous-directeur du Laboratoire de Synthèse atomique et d'Otique protonique à Ivry, il était entré à Supelec où il a créé le Laboratoire de Physique des Décharges du CNRS, d'abord implanté à Malakoff, puis transféré à Gif en 1974, et qui s'est trouvé par la suite, en 1996, associé au Laboratoire de Physique des Gaz et des Plasmas de l'Université Paris-Sud (UMR 8578).

Max Goldman n'a eu de cesse de s'intéresser aux phénomènes de base des mécanismes d'initiation et de développement spatial et temporel d'une panoplie de différents types de décharges électriques, ainsi qu'à leurs propriétés physico-chimiques, avec un souci constant de recherche de nouvelles applications.

Avec ses collègues, parmi lesquels on peut citer, entre autres, Emmanuel Marode, Gildas Hartmann, Gérard Berger, Robert Haug ainsi que Jean-Pascal Borra et Emmanuel Odic parmi les plus jeunes, et parfois en collaboration avec le Prof. Amouroux de l'Université Paris VI-ENSCP ou avec le Prof. Sigmond de l'Université de Trondheim en Norvège, il a contribué au développement de nombreux procédés plasmas (traitements de surface, paratonnerres, ozoneurs, dépollution des COV, production/filtration d'aérosols, décontamination bactérienne,...), sujets encore d'actualité puisque toujours en cours de développement dans divers laboratoires "plasma".

A ceux qui ont eu la chance de le connaître, Max Goldman laisse le souvenir d'un homme très proche de son épouse Alice dans sa vie professionnelle comme dans sa vie privée, d'un naturel optimiste, entreprenant, enthousiaste, combatif, chaleureux, toujours prêt à donner pour aider et toujours fier des vocations qu'il avait pu susciter parmi les jeunes.